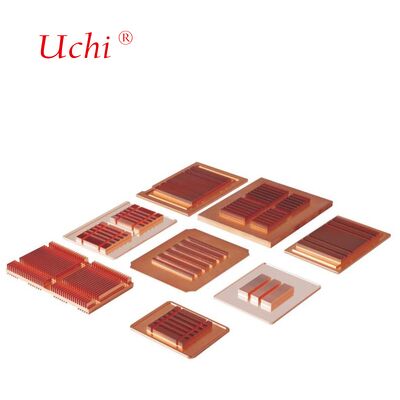

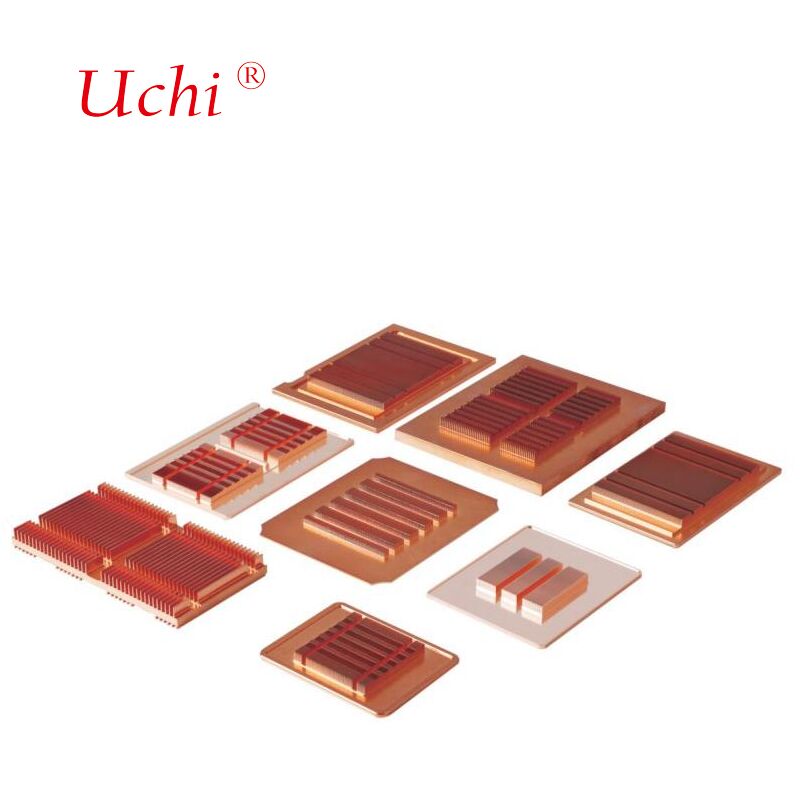

CNC เครื่องแปรรูปทองแดง ปีกระบายความร้อนสําหรับ Server Cold Plate Cooling

รายละเอียดสินค้า:

| สถานที่กำเนิด: | Dongguan, Guangdong ประเทศจีน |

| ชื่อแบรนด์: | Uchi |

| ได้รับการรับรอง: | SMC |

| หมายเลขรุ่น: | ระบายความร้อนด้วยแผ่นเย็น |

การชำระเงิน:

| จำนวนสั่งซื้อขั้นต่ำ: | 100 ชิ้น |

|---|---|

| ราคา: | โปร่ง |

| เงื่อนไขการชำระเงิน: | T/T, เพย์พาล, เวสเทิร์นยูเนี่ยน, MoneyGram |

| สามารถในการผลิต: | 50000000PCS ต่อเดือน |

|

ข้อมูลรายละเอียด |

|||

| อินเตอร์เฟซพลังงาน: | 3พิน | วัสดุ: | วัสดุทองแดง |

|---|---|---|---|

| เสียงรบกวน: | 17dbA | พลัง: | 20-500W |

| การรักษาพื้นผิว: | ต่อต้านอนุมูลอิสระ | กระบวนการ: | ครีบ skived ประสาน |

| ใบรับรอง: | ISO 9001:2000 ISO 14001:2004 | ||

| เน้น: | เครื่องบดความร้อนจากทองแดง CNC,เครื่องทําความเย็นจานเย็น,แผ่นระบายความร้อนด้วยของเหลวพร้อมการรับประกัน |

||

รายละเอียดสินค้า

CNC เครื่องแปรรูปทองแดง ปีกระบายความร้อนสําหรับ Server Cold Plate Cooling

การระบายความร้อนมีบทบาทสําคัญในการพัฒนาเศรษฐกิจดิจิทัลในฐานะมุมพื้นฐานทางกายภาพของพื้นฐานดิจิทัล และเป็นเส้นเชื่อมสําคัญที่จําเป็นในโซ่อุตสาหกรรมพลังงานคอมพิวเตอร์, เทคโนโลยีการจัดการความร้อนสนับสนุนอย่างแข็งแกร่งในฉากการณ์ดิจิตอลต่าง ๆ จากศูนย์ข้อมูลระดับประเทศคลัสเตอร์คอมพิวเตอร์ปัญญาประดิษฐ์และศูนย์คอมพิวเตอร์สูงสุดลงสู่คอมพิวเตอร์ส่วนตัว, สมาร์ทโฟนและอุปกรณ์อินเทอร์เน็ตของสิ่งของ (IoT) เป็นการสนับสนุนหลักที่แข็งแกร่งสําหรับการดําเนินงานอย่างมั่นคงและการเติบโตอย่างต่อเนื่องของเศรษฐกิจดิจิตอล

การใช้งานในอุตสาหกรรมผลิตระดับสูง

การผลิตครึ่งตัวนําและชิป

เทคโนโลยีการบรรจุพัสดุที่ก้าวหน้า (ตัวอย่างเช่น การสะสม 3 มิติ) นําไปสู่การสะสมความร้อนภายในชิป ซึ่งความสามารถในการนําความร้อนของวัสดุดั้งเดิมได้กลายเป็นอุปสรรค

AI Computing/ Data Center บริการด้านการคอมพิวเตอร์

ด้วยความหนาแน่นของกระแสความร้อนของชิป ที่เพิ่มขึ้น วิธีการทําความเย็นแบบดั้งเดิม กําลังพยายามที่จะตอบสนองความต้องการทําให้การจัดการความร้อนเป็น "เพดานที่มองไม่เห็น" ที่จํากัดการปรับปรุงพลังงานคอมพิวเตอร์.

สายการบินและอวกาศ

สภาพแวดล้อมอวกาศมีอุณหภูมิที่สูงและความว่างที่สูง ซึ่งการระบายความร้อนโดยการกระบวนการไม่เป็นไปได้ ส่งผลให้อุปกรณ์อวกาศถูกเผชิญกับอัตราการเปลี่ยนแปลงอุณหภูมิที่รุนแรง

การ ใช้ ใน ชีวิต ประจํา วัน

- อุปกรณ์ดิจิตอล:โมดูลระบายความร้อนภายในประกอบด้วยปีกเย็นโลหะถูกติดตั้งในคอมพิวเตอร์, โทรศัพท์มือถือ, คอนโซลเกมและอุปกรณ์อื่น ๆ เพื่อรับรองผลงานที่ยั่งยืนของพวกเขา

- อุปกรณ์สื่อสาร:เพื่อรับประกันความมั่นคงของการส่งและการประมวลผลข้อมูลความเร็วสูง อุปกรณ์เหล่านี้มักมีอุปกรณ์ระบายความร้อนขนาดใหญ่

- เครื่องใช้ในครัวเรือน:เครื่องปรับความร้อนและเครื่องปรับความร้อนภายนอกต้องมีประสิทธิภาพในการระบายความร้อนอย่างมีประสิทธิภาพ เนื่องจากมันจะส่งความร้อนจากพื้นที่ภายในไปภายนอกอย่างต่อเนื่อง

- อุปกรณ์การส่องแสง:การออกแบบการระบายความร้อนอย่างมีประสิทธิภาพ ให้ประกันประสิทธิภาพแสงและอายุการใช้งานที่ยาวนานของหลอดไฟ LEDการประหยัดพลังงาน ไม่แยกได้จากการสนับสนุนเทคโนโลยีการระบายความร้อน.

- รถพลังงานใหม่:รถพลังงานใหม่ต้องการระบบเย็นของเหลวที่ซับซ้อน เพื่อรักษาอุณหภูมิการทํางานที่ดีที่สุด

ความท้าทายในการผลิตการระบายความร้อนแบบดั้งเดิม

- เทคโนโลยีทําความเย็นด้วยอากาศแบบดั้งเดิม ไม่สามารถตอบสนองความต้องการความหนาแน่นของกระแสความร้อนที่มากกว่า 50W / cm2 สําหรับโปรเซสเซอร์ที่มีประสิทธิภาพสูง เช่น ชิป AI อีกต่อไป

- ผลประกอบของวัสดุที่นําไฟได้ถึงจุดขัดขวาง และสัดส่วนการนําไฟของไขมันที่นําไฟได้ทั่วไปยากที่จะเกิน 5W/m*K

- แม้ว่าเทคโนโลยีการเย็นของเหลวจะให้ผลงานที่ดีกว่า แต่มันมีกระบวนการการผลิตที่ซับซ้อนและความต้องการทางเทคนิคสูง

การแปลงและปรับปรุงสินค้า

สาขาอุตสาหกรรมการระบายความร้อนกําลังผ่านการเปลี่ยนแปลงทางกลยุทธ์จากอุตสาหกรรมที่สนับสนุนไปยังสาขาเทคโนโลยีหลักที่สําคัญ เส้นทางการปรับปรุงของมันถูกกําหนดอย่างชัดเจน:

- เทคโนโลยีการเปลี่ยนจากการระบายความร้อนแบบเรียบร้อยไปสู่การควบคุมอุณหภูมิระดับแม่นยํา โดยมีเทคโนโลยีการเย็นของเหลวปรากฏขึ้นเป็นทางแก้ปัญหาหลัก

- การตั้งตําแหน่งอุตสาหกรรม:การเปลี่ยนจากผู้ผลิตไปเป็นผู้ให้บริการทางการแก้ไข "การระบายความร้อนเป็นบริการ"

- ระบบวัสดุ:การพัฒนาไปสู่ความสามารถในการนําความร้อนสูงและความฉลาด

- การผลิตแบบจําลอง:การบูรณาการด้านดิจิตอลและการผลิตสารเพิ่มเติม

โดยพื้นฐานแล้ว การเปลี่ยนแปลงนี้คือการปฏิวัติความเป็นตัวตน จากกระบวนการช่วยสู่การออกแบบนําความสามารถในการระบายความร้อนได้กลายเป็นหนึ่งในตัวชี้วัดหลักในการวัดความสามารถในการแข่งขันของเศรษฐกิจดิจิทัล.

การออกแบบเรเดียเตอร์แผ่นเย็น

การออกแบบกระแสการไหลผ่านภายในที่กําหนดเอง โดยใช้ข้อมูลการบริโภคพลังงานของลูกค้า และรูปแบบการกระจายความร้อนกระบวนการวิศวกรรมของเรารวมถึงการวิเคราะห์การจําลองที่ครบถ้วน ด้วยการปรับปรุงปริมาตรแบบซ้ําซ้ํา เพื่อบรรลุเป้าหมายการทํางานแบบอุณหภูมิและไฮดรอลิกที่ดีที่สุด.

ความสามารถในการผลิตของบริษัท

โรงงานจําหน่ายหม้อของเรามีเครื่องจักรไฟฟ้า (EDM) จํานวน 22 ชุด มีหลายชนิด รวมถึงเครื่องจักร EDM กระจก 2 เครื่อง MAKINOซึ่ง 3 เครื่องคือ Seibu และ 1 เครื่องคือ Sodick ที่นําเข้าจากญี่ปุ่นนอกจากนี้ โรงงานยังมีเครื่องชํารุดกระเทียม 7 เครื่อง เครื่องบด 10 เครื่อง เครื่องบด 2 เครื่อง และเครื่องหมุน 1 เครื่อง

อุปกรณ์และความสามารถของฮาร์ดแวร์ที่มีพลัง

| ขนาดตาราง | 500 × 350 มม |

| ความเร็วในการเคลื่อนที่เร็ว | 5000 มิลลิเมตร/นาที |

| น้ําหนักของชิ้นงานสูงสุด | 500 กิโลกรัม |

| น้ําหนักอิเล็กตรอนสูงสุด | 50 กิโลกรัม |

ความแม่นยําในการแปรรูปสูง

การนําเทคโนโลยีใหม่ SuperSpark4 และ IES (Intelligent Expert System) มาใช้เราให้อุปกรณ์อํานวยพลังงานปรับปรุงที่ก้าวหน้าและการควบคุมกระโดดเพื่อทําให้กระบวนการ EDM ได้มั่นคงและปรับปรุงความแม่นยําของการแปรรูปพร้อมกันพร้อมด้วยเทคโนโลยีกําเนิด ultra-surface และ ultra-edge ที่ทันสมัย ห้องประกอบงานสามารถบรรลุการเสร็จผิวที่ดีที่สุดและคุณภาพโลหะ

เทคโนโลยีระบบเย็นของเหลว

ระบบเย็นของเหลวพลังงานสูง ต้องการระบายความร้อนที่สามารถดูดซึมความร้อนอย่างรวดเร็วระบบของเราส่งความร้อนจํานวนมากผ่านการไหลของของเหลว, สามารถระบายความร้อนตั้งแต่หลายร้อยวัตต์ถึงมากกว่าหนึ่งกิโลวัตต์

ชนิดของแผ่นเย็นเหลว

- พล็อตเย็นเหลวหลอดฝัง:ผลิตโดยแผ่นกระจก, ขุมและสวมท่อทองแดงภายใน, จากนั้นปิด hermetically โดยการสวม.และความเรียบสูงสําหรับการสัมผัสกับอุณหภูมิที่ดี.

- พล็อตเย็นเหลวแบบท่อใส่:ผลิตโดยการแทงท่อทองแดงบนพื้นผิวแผ่นอลูมิเนียม โดยใช้กระบวนการผสมผสานหรือผสมผสาน โดยมีการควบคุมความเรียบของแผ่นที่เข้มงวดเพื่อความต้านทานทางความร้อนที่ต่ําที่สุด

- ชนิดช่องจานเย็นเหลว:ช่องทางการไหลผ่านภายในที่สร้างขึ้นบนสับสราตทองแดงหรืออลูมิเนียมโดยการเจาะ, extrusion, และการแปรรูปความแม่นยํา, ปิดด้วยการปั่นด้วยการขัดหรือการผสมความร้อนสูง

- บล็อกเย็นของเหลว:สําหรับการระบายความร้อนชิปพลังงานสูง ด้วยช่องทางการไหลผ่านภายในที่สร้างขึ้นโดยใช้เทคโนโลยีปีกสกิวิง เพื่อให้พื้นที่ผิวแลกเปลี่ยนความร้อนสูงที่สุด

การใช้งานสินค้า

การประกันคุณภาพ

เรารักษามาตรฐานคุณภาพอย่างเข้มงวด ด้วยอุปกรณ์การทดสอบที่ครบถ้วน รวมถึง:

- 1 เครื่องวัดพิกัด

- 1 เครื่องฉายภาพ

- 2 เครื่องทดสอบน้ําแรงดันสูง

- 4 เครื่องทดสอบความต้านทานทางความร้อน

- 2 เครื่องทดสอบการรั่วไหลของของเหลว

ความมุ่งมั่นในการบริการลูกค้า

- การตอบสนองอย่างรวดเร็วต่อทุกคําถาม

- ราคาที่แข่งขันกับคุณภาพที่รับประกัน

- โปรแกรมการผลิตที่มีประสิทธิภาพ

- การแก้ไขการขนส่งที่ดีที่สุด

- การสนับสนุนทางเทคนิคครบวงจร

คํา ถาม ที่ ถาม บ่อย

คุณเป็นบริษัทพาณิชย์หรือผู้ผลิต?

เราเป็นผู้ผลิตอุปกรณ์ระบายความร้อนและแผ่นระบายน้ําที่มีประสบการณ์มากมายและทีมงานทางเทคนิคที่แข็งแกร่ง

คุณเคยส่งออกสินค้ามาก่อนแล้ว และไปยังภูมิภาคไหน?

60% ของผลิตทั้งหมดของเราถูกส่งออกไปยังญี่ปุ่น อินเดีย อังกฤษ แคนาดา สหรัฐอเมริกา และบราซิล

คุณมีพนักงานกี่คน

มีประมาณ 100 พนักงานทั่วฝ่ายขาย, ซื้อ, วิศวกรรม, QA, โกดัง, และฝ่ายผลิต

คุณสามารถให้ตัวอย่างถ้าเราเห็นด้วยกับการออกแบบได้หรือไม่

ใช่ เราให้ตัวอย่างเพื่อยืนยันก่อนการผลิตจํานวนมาก พร้อมกับภาพวาดเทคนิคถ้าจําเป็น

คุณใช้วิธีการบรรจุอะไร?

การบรรจุที่กําหนดเองด้วยกล่องกระดาษธรรมดา และผ้าที่กันความแน่น หรือกล่องกระดาษไม้ เพื่อการป้องกันที่ดีที่สุดระหว่างการขนส่ง

คุณให้การสนับสนุนทางเทคนิคสําหรับปัญหาสินค้าหรือไม่

ผลิตภัณฑ์ทั้งหมดได้รับการตรวจสอบอย่างครบถ้วน ก่อนการจัดส่ง สําหรับปัญหาใด ๆ เราให้คําตอบทางเทคนิคทันที

ต้องการทราบรายละเอียดเพิ่มเติมเกี่ยวกับผลิตภัณฑ์นี้